SR SP5 CZ (Oxygen Online Analyser)

Price 20350 INR/ Piece

SR SP5 CZ (Oxygen Online Analyser) Specification

- Automation Grade

- Automatic

- Dimension (L*W*H)

- 98*98*100 Centimeter (cm)

- Gas Pressure

- 0.1 - 0.3 MPa mpa

- Frequency

- 50/60 Hz Hertz (HZ)

- Interface Type

- RS485/4-20 mA

- Temperature

- -10C to 60C Celsius (oC)

- Humidity

- 0-95% RH (non-condensing)

- Response Time

- 30 seconds Seconds

- Operating Voltage

- 220 VAC Volt (V)

- Port Size

- 1/4 inch NPT

- Equipment Type

- Oxygen Online Analyser

- Display Type

- Digital

- Max Height

- 100 mm

- Mounting Type

- Panel Mount

- Power Supply

- 220 VAC

- Resolution

- 0.01% O

- Application

- Continuous oxygen monitoring in industrial gases

- Test Range

- 0-25% O

- Number of Specimens

- 1

- Features

- Real-time monitoring, high reliability, easy installation

- Usage

- Online analyser

- Machine Weight

- 1 Kilograms (kg)

- Control Mode

- Automatic

SR SP5 CZ (Oxygen Online Analyser) Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 30 Per Month

- Delivery Time

- 2 Days

- Packaging Details

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Yes

About SR SP5 CZ (Oxygen Online Analyser)

THE TECHNOVATION MODEL SP-5CZ OXYGEN ANALYZER is ZERO and CAL potentiometers provided

Confidence flash provided

Quick and accurate response to Oxygen

Programmable Alarms configuration, Both alarmshigh OR one high and one low. Settable throughout the range

Recorder output 0 - 1 V and 4 - 20mA

APPLICATIONS

MODEL SP-5 CZ is specifically designed for use in Oxygen /Nitrogen plants where the vented gases are mainly Nitrogen / Oxygen. Monitoringthe vent gases could tell when the % oxygen in nitrogen stream or vice versahas reached an abnormally high or low % necessitating corrective action withinthe plants operational parameters so as to reduce the wasted gas and increaseoutput. A single percent of oxygen reduced in the vent gases would increase theproduction by the equivalent amount leading to a one percent improvement in theplants production

STANDARD SPECIFICATIONS

Display : LED 12 mm high, with 3 digit

Range : 0 to 25 % OR 0-100% O2

Resolution : 0.1 %steps

Accuracy : 2 %FSD at constant temp & pressure

Power Supply : 220 VAC, 50Hz, 1 Phase.

Sensor type :Electrochemical

Sensor mounting : At end of cable of 1.5 Mts.

Working temp : 0 to 45 OC

Calibration : By ambient air or certified calibration gas

Size : 98x 98 x 100 mm depth

Weight : 1 Kg.Approx.

Sensor life in AIR : 24 monthsExpected

Alarms : Twoaudible & visible.

Alarm relay : One setNO, C, NC contact of 50 VA rating provided per alarm.

Panel cutout size : 90 x 90 mm

Analog Output : 0-1 V and4-20 mA.

Flow : 0.1 0.2 LPM

Precise Oxygen Monitoring for Industrial Applications

The SR SP5 CZ Oxygen Online Analyser ensures reliable, real-time measurement of oxygen levels in industrial gases. With its advanced electrochemical sensor and automated control mode, it delivers precise readings crucial for safety and process optimization. Its robust design withstands challenging environments, from 0-95% humidity and -10C to 60C temperatures, making it suitable for a wide range of industries.

Advanced Features and User-Friendly Operation

Equipped with a digital display and multiple interface options, such as RS485 and 4-20 mA, the SR SP5 CZ simplifies monitoring and data integration. The analyser supports easy installation via panel mounting, and the calibration interval of every six months reduces maintenance requirements. Real-time alarm outputs offer immediate notification for safe operation and rapid response.

Durability and High Performance for Continuous Use

Housed in IP65 ABS plastic, the analyser is engineered for durability and long-term function. Its compact dimensions (98*98*100 cm) and lightweight design (1 kg) facilitate seamless implementation. The measurement range covers 0-25% O with fine resolution (0.01%), supporting a diverse range of industrial applications where accurate oxygen analysis is indispensable.

FAQs of SR SP5 CZ (Oxygen Online Analyser):

Q: How is the SR SP5 CZ Oxygen Online Analyser installed in an industrial setting?

A: The SR SP5 CZ analyser is designed for panel mounting, allowing seamless integration into existing equipment setups. Its compact size and standard 1/4 inch NPT port size make installation straightforward in control panels or monitoring stations.Q: What is the calibration process for this analyser, and how often should it be done?

A: Calibration involves exposing the sensor to a known oxygen concentration and adjusting the readings accordingly. The manufacturer recommends calibration every six months to maintain peak accuracy and reliability.Q: When should the alarm output be configured, and what benefits does it provide?

A: Alarm output configuration is recommended during initial setup, especially if safety protocols require immediate response to oxygen level deviations. The optional relay output enables automatic alerts and system shutdowns to ensure prompt intervention and equipment protection.Q: Where can the analyser be used within industrial environments?

A: Thanks to its IP65 ingress protection and operational range (0.10.3 MPa gas pressure, 095% RH humidity, -10C to 60C temperature), the analyser can be safely used in various industrial gas monitoring locations, including manufacturing plants, refineries, and process facilities.Q: What gas types is the SR SP5 CZ suitable for monitoring?

A: This equipment is specifically designed for continuous oxygen monitoring in industrial gases. It accurately detects oxygen concentrations ranging from 0% to 25%, ensuring suitability for diverse gas applications.Q: How does automatic control mode benefit daily operations?

A: Automatic control mode streamlines system management by maintaining real-time oxygen monitoring without manual intervention. It enhances safety, reduces human error, and improves overall operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oxygen Analyzer Category

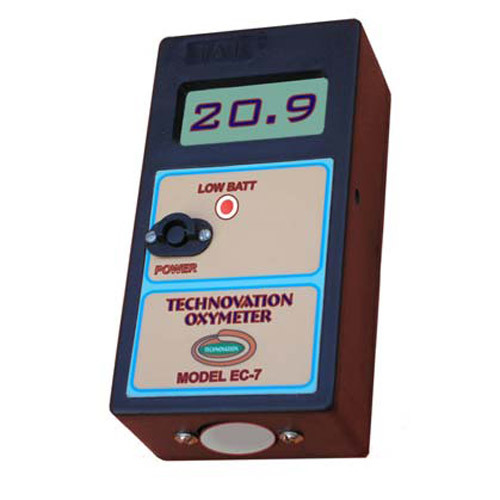

EC-3 Mini Oximeter

Price 25500.00 INR / Unit

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 13*65*65 Centimeter (cm)

Power Supply : 9V (Dry Cell)

Application : Portable Safety Analyser

Power : 9V Volt (v)

SR -OX 11-15-(Oxygen PPM Analyzers-Online and Portable)

Price 37000 INR / Unit

Minimum Order Quantity : 1 , , Number

Dimension (L*W*H) : 220*160*110 Millimeter (mm)

Power Supply : 220 V AC

Application : Testing & Measurement

Power : 220 VAC Volt (v)

EC 7 MAP -MAP Analyzer (Food packet Testing Oxygen Meter)

Price 18500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 130*65*45 Millimeter (mm)

Application : Food Packet Testing

Power : 9 Volt (v)

EC 7 MAP. FOR Food packet testing

Price 16400.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Application : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry