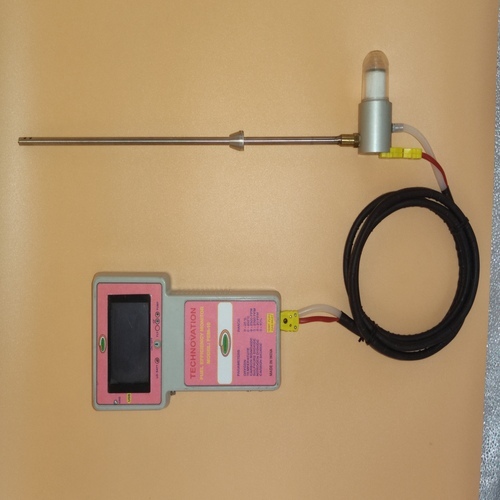

SR FEM 10

Price 40000.0 INR/ Number

SR FEM 10 Specification

- Display Type

- Digital Touch Screen

- Operating Voltage

- 220V Volt (V)

- Frequency

- 50 Hz Hertz (HZ)

- Interface Type

- USB/RS232

- Equipment Type

- Foam Compression Testing Machine

- Automation Grade

- Automatic

- Features

- Data Recording, Touchscreen Interface, Overload Protection

- Number of Specimens

- 1

- Gas Pressure

- 0.5~1.0 MPa mpa

- Max Height

- 700 mm

- Accuracy

- 1% of reading %

- Temperature

- 10C40C Celsius (oC)

- Port Size

- 1/4 BSP

- Application

- Foam Elasticity & Resilience Measurement

- Power Supply

- AC 220V, 50Hz

- Resolution

- 0.01 N

- Test Range

- 101000 N

- Humidity

- 20%80% RH

- Mounting Type

- Floor Mounted

- Specimen Size

- Width 50 mm Length 200 mm Millimeter (mm)

- Response Time

- <0.5 s Seconds

- Usage

- Material Testing (Foam)

- Machine Weight

- 65 kg (approx) Kilograms (kg)

- Test Speed

- 50300 mm/min (adjustable)

- Test Width

- 50 mm Millimeter (mm)

- Test Stroke

- 500 mm

- Control Mode

- Touch Screen PLC Based

SR FEM 10 Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Per Month

- Delivery Time

- 6 Days

- Main Domestic Market

- All India

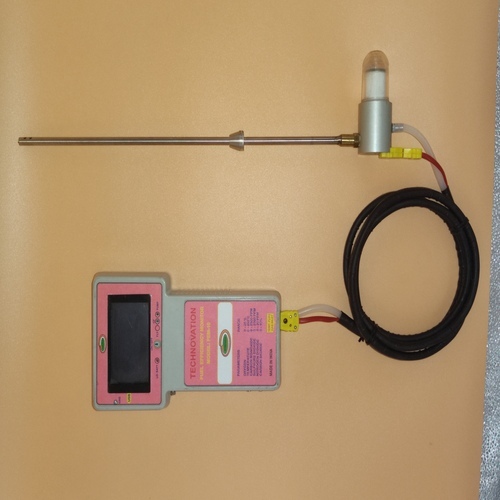

About SR FEM 10

APPLICATIONS

Measurement of exhaustgases of Boilers,

Furnaces, Heaters, Kilns in order to improve combustionefficiency and reduction of pollutant gases released by these devices

STANDARD SPECIFICATIONS

Display : 3.5 TFT Colored LCDwith Touch Screen

Power :3.7 V LiONrechargeableBattery

Lowbattery : Indicationprovided.

In-BuiltPump :6" Hg suction,0.7 LPM flow

WorkingTemp. : 5 TO45C

Sensors :Electrochemical. NDIRand pellistoroptions. Expected life for O2 is 2 yrs & EC is 3 yrs.

Size&Wt :23x13x4.5cm & 0.8kg.

Temp. probe :Thermocouple, K type

Probelength : 60 cm CopperTube

Probe : GasCoolerandfilterintegral

Datastorage :Upto400readings

Dataoutput : USBport.

Gases&Ranges :Instrument suppliedwith Oxygen &temperature sensors, additional sensors available as per table below

High Precision Foam Testing

The SR FEM 10 is engineered for accurate evaluation of foam elasticity and resilience, matching international standards like ASTM D3574 and ISO 2439. Its advanced sensors and intuitive touchscreen PLC provide reliable, repeatable results for manufacturers, exporters, and quality control professionals.

User-Friendly Operation and Data Handling

With its digital PLC touchscreen interface, the SR FEM 10 simplifies test configuration and operation. Data can be conveniently exported in CSV or PDF formats for analysis and record-keeping, accessible via USB or RS232 interfaces, making the process efficient and secure.

Comprehensive Safety and Calibration

Operator safety is paramount with emergency stop functions and limit switch protection. The user-calibrated standard weights method ensures ongoing testing accuracy. Overload protection helps preserve equipment longevity, while the robust construction supports rigorous daily use.

FAQs of SR FEM 10:

Q: How do I calibrate the SR FEM 10 Foam Compression Testing Machine?

A: Calibration is performed by the user using standard weights. This allows you to ensure measurement accuracy with each testing session, maintaining results within 1% of the reading.Q: What type of data output does the machine support, and how can I access it?

A: The SR FEM 10 supports CSV and PDF data output formats. Data can be accessed through USB or RS232 interfaces, allowing seamless integration with your data management systems.Q: When is it necessary to use the emergency stop feature?

A: The emergency stop function should be used immediately in the event of unexpected machine behavior or any hazardous situation to prevent injury or equipment damage.Q: Where can this machine be installed, and what are its mounting requirements?

A: The SR FEM 10 is designed for floor mounting, ideal for laboratory or production environments with stable flooring. Ensure it is placed in an area with appropriate ventilation, stable power supply (AC 220V, 50Hz), and environmental conditions within 1040C and 20%80% RH.Q: What process does the machine follow during foam testing?

A: The process involves placing a foam specimen (50 mm 200 mm) in the test area. The machine, controlled via touchscreen PLC, applies a precise compressive force in the range of 101000 N at adjustable speeds (50300 mm/min), and records the materials response for compliance with ASTM or ISO standards.Q: How does the SR FEM 10 benefit material testing in foam applications?

A: The machine delivers highly accurate (1%) and repeatable measurements of foam elasticity and resilience. Automatic control, adjustable test speeds, and real-time digital display improve efficiency and reliability, supporting robust quality control in foam manufacturing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Gas Analyzer Category

SR FEM 7- (Fuel Gas Monitor)

Price 42000 INR

Minimum Order Quantity : 1 Piece

Usage : Fuel

Product Type : Fuel Gas Monitor

Power Supply : Battery

Features : 1 to 2

MODEL FGM % 02, CO FLUE-GAS MONITOR

Price 23500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Portable Gas Analyser

Power Supply : 12v

Features : Good Quality

Temprature Fuel Gas Monitor

Minimum Order Quantity : 1 Piece

Usage : Laboratory

Product Type : Temprature Fuel Gas Monitor

Power Supply : Electric

Features : Accurate

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry