MODEL 16CTS

Price 23500.0 INR/ Piece

MODEL 16CTS Specification

- Usage & Applications

- Industrial and Commercial Gas Monitoring

- Automation Grade

- Automatic

- Sensor Type

- Electrochemical / Semiconductor

- Instruments Type

- Gas Detector

- Display Type

- LED

- Measurement

- PPM Level Toxic Gas Concentration

- Power Source

- Electric

- Efficiency

- >95%

- Temperature

- 0C to 55C Celsius (oC)

- Orientation

- Wall Mounted

- Product Type

- Toxic Gas Detector

- Material

- ABS Plastic Enclosure

- Cooling System

- Air Cooled

- Noise Level

- < 35 dB db

- Voltage

- 230V AC Volt (v)

- Weight

- 2.5 Kilograms (kg)

- Dimension (L*W*H)

- 280*280*130 Millimeter (mm)

- Surface

- Smooth

- Output

- 4-20mA / Relay / RS485

- Response Time

- < 30 seconds

- Operating Humidity

- 10% to 95% RH non-condensing

- Protection Level

- IP65

- Reset Function

- Yes

- Alarm

- Buzzer and Visual

- Mounting

- Screw Mount

MODEL 16CTS Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 5 Days

- Packaging Details

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Yes

About MODEL 16CTS

|

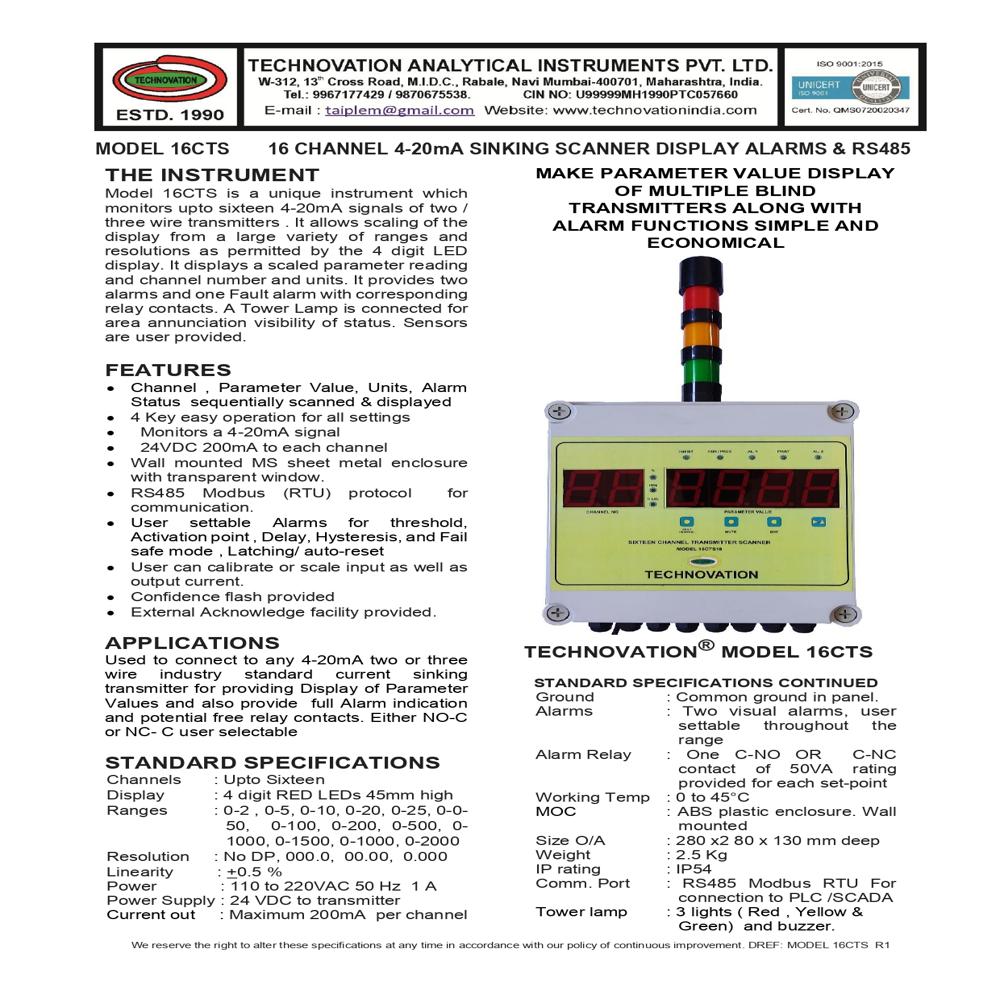

THE INSTRUMENT Model 16CTS is a unique instrument which monitors upto sixteen 4-20mA signals of two / three wire transmitters . It allows scaling of the display from a large variety of ranges and resolutions as permitted by the 4 digit LED display. It displays a scaled parameter reading and channel number and units. It provides two alarms and one Fault alarm with corresponding relay contacts. A Tower Lamp is connected for area annunciation visibility of status. Sensors are user provided.

FEATURES Channel , Parameter Value, Units, Alarm Status sequentially scanned & displayed 4 Key easy operation for all settings Monitors a 4-20mA signal 24VDC 200mA to each channel Wall mounted MS sheet metal enclosure with transparent window. RS485 Modbus (RTU) protocol for communication. User settable Alarms for threshold, Activation point , Delay, Hysteresis, and Fail safe mode , Latching/ auto-reset User can calibrate or scale input as well as output current. Confidence flash provided External Acknowledge facility provided. APPLICATIONSUsed to connect to any 4-20mA two or three wire industry standard current sinking transmitter for providing Display of Parameter Values and also provide full Alarm indication and potential free relay contacts. Either NO-C or NC- C user selectable STANDARD SPECIFICATIONSChannels : Upto Sixteen Display : 4 digit RED LEDs 45mm high Ranges : 0-2 , 0-5, 0-10, 0-20, 0-25, 0-0-50, 0-100, 0-200, 0-500, 0-1000, 0-1500, 0-1000, 0-2000 Resolution : No DP, 000.0, 00.00, 0.000 Linearity : +0.5 % Power : 110 to 220VAC 50 Hz 1 A Power Supply : 24 VDC to transmitter Current out : Maximum 200mA per channel Ground : Common ground in panel. Alarms : Two visual alarms, user settable throughout the range Alarm Relay : One C-NO OR C-NC contact of 50VA rating provided for each set-point Working Temp : 0 to 45C MOC : ABS plastic enclosure. Wall mounted Size O/A : 280 x2 80 x 130 mm deep Weight : 2.5 Kg IP rating : IP54 Comm. Port : RS485 Modbus RTU For connection to PLC /SCADA Tower lamp : 3 lights ( Red , Yellow & Green) and buzzer |

|

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Quality Monitors Category

SR 90-Ambient Air Quality Monitor

Price 25700.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : LCD Display

Automation Grade : Automatic

Voltage : 230 V AC, 50 Hz Volt (v)

Usage & Applications : Ambient Air Quality Monitoring, Environmental Monitoring

AS2 GENERAL PURPOSE AIR SAMPLER

Price 20000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : No

Automation Grade : Automatic

Voltage : 220440 Volt (v)

Usage & Applications : Industrial

BAQM R1 BREATHING AIR QUALITY MONITOR

Price 41000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital

Automation Grade : Automatic

Voltage : 220440 Volt (v)

Usage & Applications : Industrial

90N AMBIENT AIR QUALITY MONITOR

Price 32000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Display Type : Digital

Automation Grade : Automatic

Voltage : 220440 Volt (v)

Usage & Applications : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry